URSA technicians are experts in finding out the root cause of the problems, proposing remote assistance when possible, but also fixing the problem onboard whether mechanical, electrical or related to software.

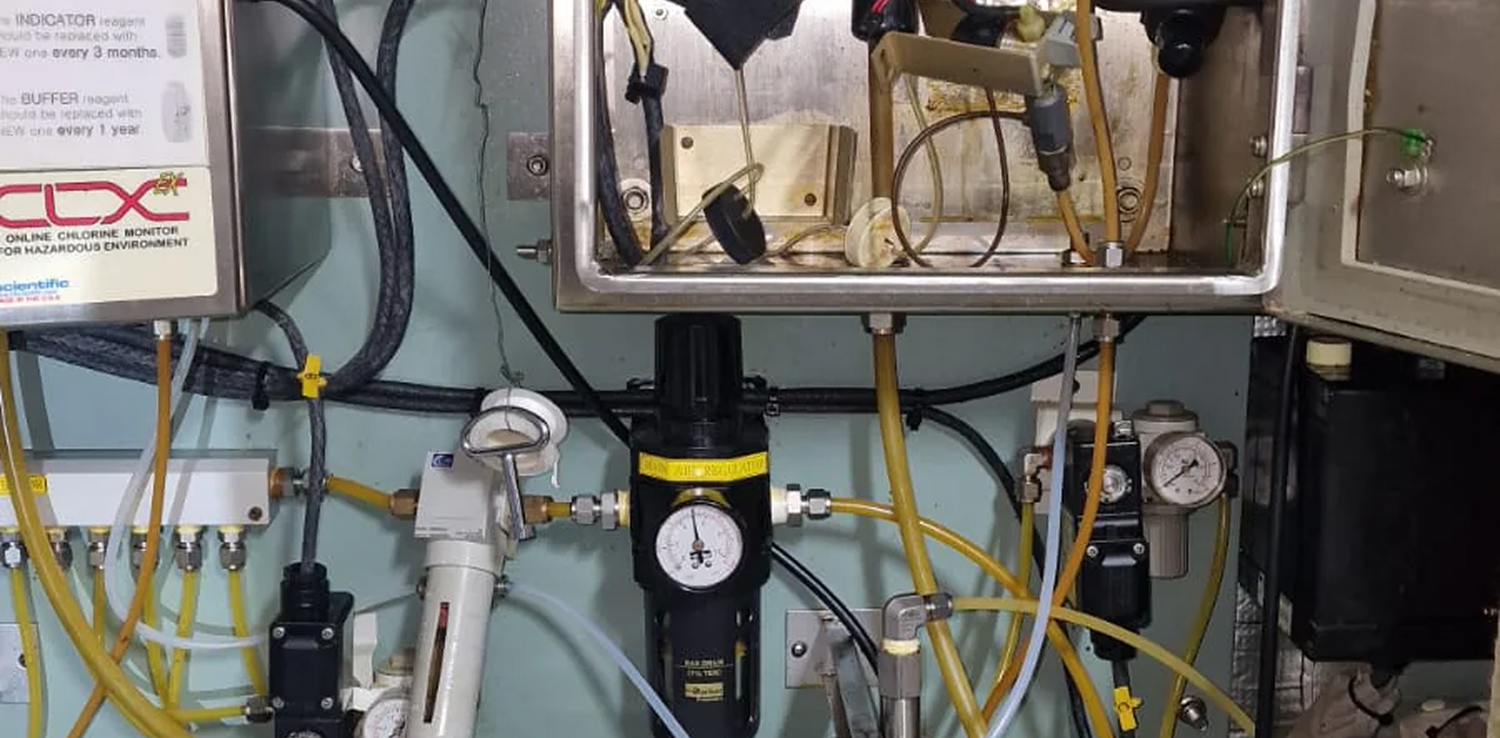

A typical job shown here is dismantling a TRO meter completely, stripping and cleaning every part, replacing broken ones and putting it back together working as new.

BWMS Spare Parts

Through our network worldwide, we have access to all spare parts that BWMS require to operate correctly. We are exclusive providers for some of the essential spare parts needed for operating BWMS. We list some of the spare parts that are commonly ordered from our web shop, however, if you require other items, feel free to send us a request and we will be in touch to accommodate your needs.